産(chǎn)品介紹

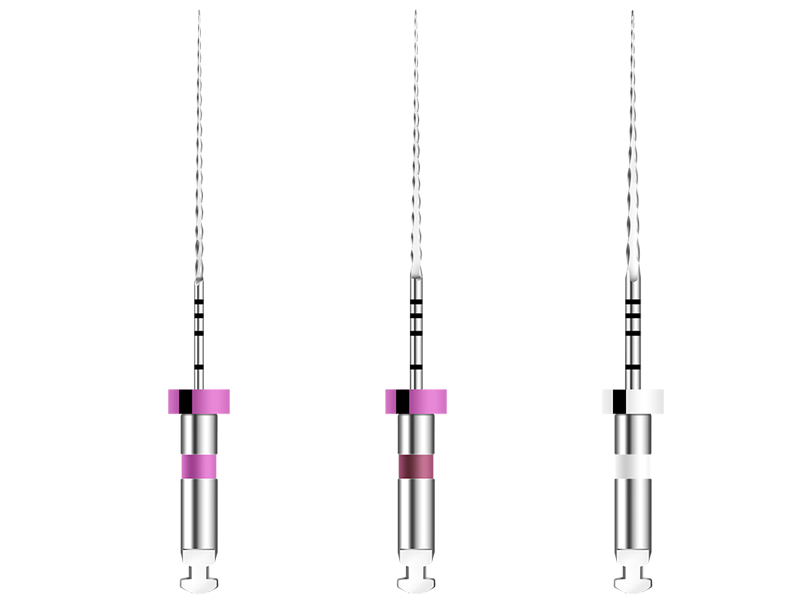

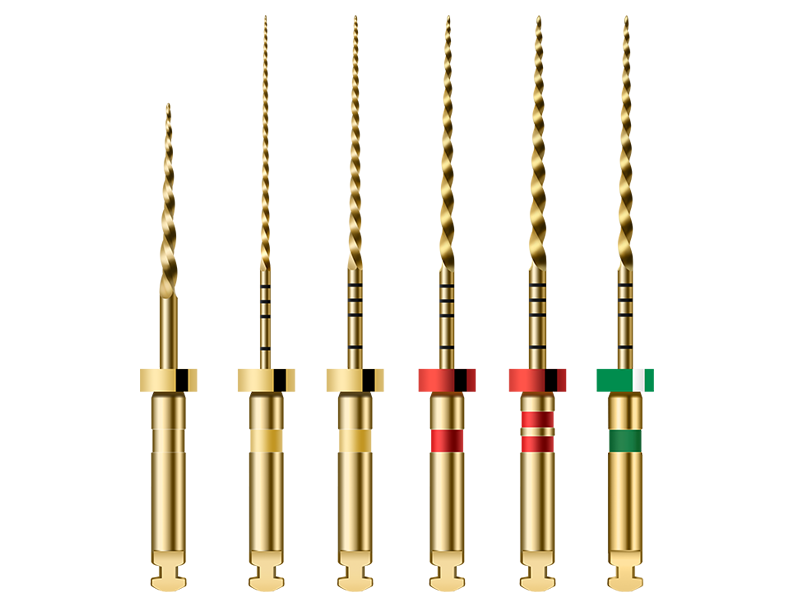

◆ Unique slitting design

At the same time, the chip removal space is increased, and the torque of the "embedding force" is effectively inhibited into the cutting force, which greatly improves the working efficiency of the file

◆ Profile thread cutting design

1, chip removal space increased by 30% 2, toughness improved 3, anti-fatigue performance improved

◆ Focus on dredging and simplifying preparation

1, the root canal embedding force is reduced; 2, the root canal micro-cracking probability is reduced; 3, the root tip deviation probability is reduced

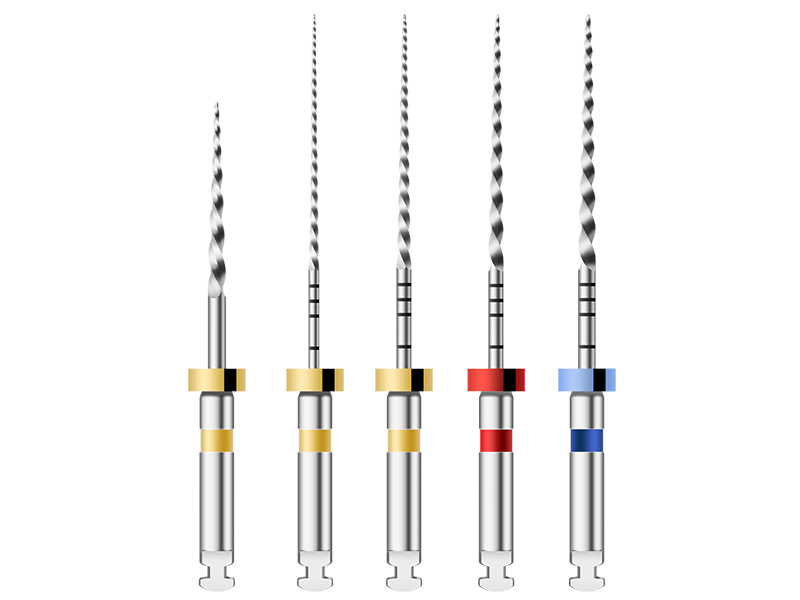

◆ Product highlights

Better flexibility better folding resistance stronger cutting force stronger chip removal force Easy to find deformation easy to separate and handle

At the same time, the chip removal space is increased, and the torque of the "embedding force" is effectively inhibited into the cutting force, which greatly improves the working efficiency of the file

◆ Profile thread cutting design

1, chip removal space increased by 30% 2, toughness improved 3, anti-fatigue performance improved

◆ Focus on dredging and simplifying preparation

1, the root canal embedding force is reduced; 2, the root canal micro-cracking probability is reduced; 3, the root tip deviation probability is reduced

◆ Product highlights

Better flexibility better folding resistance stronger cutting force stronger chip removal force Easy to find deformation easy to separate and handle

産(chǎn)品詳情

Order of operation:

Unclog the root canal by hand with a 10-gauge stainless steel file.

Use open file (1708), pre-open crown square and middle upper.

Measure the working length with a 10 gauge stainless steel K file and prepare to the root tip with a 15 gauge stainless steel K file.

Machine channel file (1902) to create smooth channels.

Then select the appropriate M3-L platinum file and prepare it to the same length. (If it is difficult to go down, you can also pre-open the upper 1/3 with an open file before).

Every time the file is changed, rinse with a flushing solution (sodium hypochlorite is recommended), and use a No. 10 stainless steel file to return the file.

Home

Home

Product

Product

News

News

Contact

Contact